Building a company worth working at

A safe and healthy working environment

We strive to create a safe and healthy working environment and promote health among employees working in the Haseko Group and employees of partner companies.

Toward the realization of a safe and healthy working environment

Policy for safety and health

At the Haseko Group, we establish a Group-wide “Basic Policy for Safety and Health Management” that stipulates a safety and health policy for Group employees each year, execute thoroughgoing initiatives to eliminate occupational accidents and work to create safe and comfortable workplaces on an ongoing basis.

Furthermore, construction sites of Haseko Corporation establish a safety and health policy and specific implementation measures including partner companies under the Safety and Health Management Plan each year. In order to minimize occupational accidents, not to mention reducing fatal and serious accidents/disasters to zero, we treat the elimination of factors that cause human errors as a priority issue in our activities.

Fiscal 2025 Group-wide Basic Policy for Safety and Health Management (Company-wide)

[I] Slogan

“Let’s expand comfortable workplaces and promote workstyle reform”

[II] Policies and measures

In fiscal 2025, in addition to thoroughly promoting initiatives to eliminate occupational accidents in each business site, Safety and Health Committee members at each company will take the lead in creating a safe and comfortable workplace environment. In addition, under the leadership of the heads of each business site, we will foster creativity and ingenuity to address long working hours as part of workstyle reform.

<Policy>

- Awareness activities for a safe and comfortable workplace

We will conduct year-round campaigns and preventive activities concerning safety and health, including reducing occupational accidents.

Strengthen the Safety and Health Committees at each business site and continuously raise awareness throughout the company. - Strengthening of the industrial doctor system

We will continue to strengthen the industrial doctor system to further enhance health management and safety and health activities. - Initiatives to improve productivity and address long working hours

Under the Workstyle Reform Promotion Policy, we will continue various initiatives aimed at improving productivity and addressing long working hours in coordination with MOSt Activities.

<Measures>

- Take measures to achieve our goal of zero occupational accidents (employee awareness-raising activities, e.g. use of posters and bulletin boards)

- Thoroughly disseminate Safety and Health Committee minutes to all officers and employees by posting them online

- Continue to follow up to ensure the industrial doctor system and safety and health activities of each group company are implemented more effectively

- Promote smoking cessation at all group companies. Implement smoking cessation measures by continuing to hold No Smoking Day and utilizing online smoking cessation programs

- Continue to hold standard first aid training sessions to prepare for appropriate initial response in the event of an accident

- Promote initiatives aimed at realizing two days off a week at construction sites

- Take measures based on the status of infectious disease outbreaks (COVID-19, influenza)

*Health maintenance and improvement efforts are conducted under the “Healthy HASEKO Full-of-life Plan,” a health management promotion activity that fulfills the health management aspect of safety and health activities.

Group Basic Policy for Safety and Health Management (Japanese Only) [PDF:150KB]

Haseko Corporation Construction Sites Safety and Health Management Plan (Japanese Only) [PDF:3.24MB]

*The Haseko Corporation Safety and Health Management Plan applies to Haseko Corporation’s construction sites and partner companies that undertake construction work.

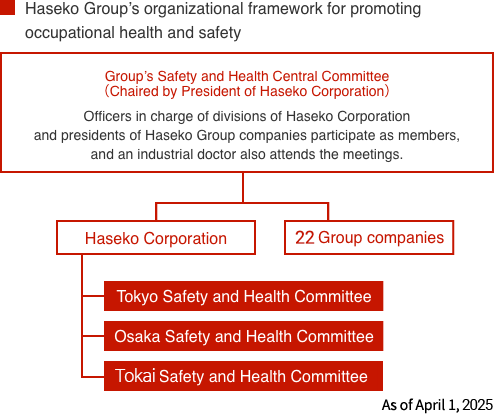

Framework for promoting health and safety

Although the Haseko Group has not been accredited with Occupational Health and Safety Management Systems ISO 45001 (formerly OHSAS 18001), it has voluntarily set up the Safety and Health Central Committee as a supervisory system in which directors oversee safety matters, chaired by the President and Representative Director of HASEKO Corporation to administer the respective Safety and Health Committees.

In fiscal 2024, with “Eliminate the occurrence of human error and aim for zero accidents and zero disasters” as our slogan, we executed thoroughgoing initiatives to eliminate occupational accidents at each business site, and committee members for safety and health promotion of each company continuously played a central role in creating a safe and comfortable workplace environment.

For elimination of occupational accidents, we conducted activities by setting the frequency rate of occupational accidents at 0.60 or less and the severity rate of occupational accidents at 0.01 or less as target figures for accidents* at construction sites. For the creation of a safe and comfortable workplace environment, we further promoted non-working days together with workers in order to rectify long hours of work as part of Workstyle Reform at construction sites. We also made Group-wide efforts in this area at the organization level in collaboration with MOSt Activities.

*Target for occupational accidents resulting in four or more days of absence from work at Haseko Corporation

At meetings of the “Safety and Health Central Committee,” the President and Representative Director of Haseko Corporation, who chairs the committee, and the committee members, comprising the officers in charge of each department and the presidents of each Group company, as well as the representatives of the labor union of the Haseko Group, participate in deliberations and discussions regarding safety and health. At the Safety and Health Committees of Group companies, members nominated by the labor union of the Haseko Group and those who represent a majority of the employees.

Activities to raise safety awareness

To eliminate occupational accidents, it is essential that each and every employee act in his/her day-to-day work with safety in mind.

In addition to proactive utilization of posters and bulletin boards to help raise employees’ awareness, we conduct risk assessment through regular safety patrolling at the Group’s construction sites where everything takes place to ensure safety management.

Regarding safety and health education for its own employees, Haseko Corporation implements training each fiscal year on matters such as the basic points of laws, regulations, and rules related to safety and health, the key points in managing each type of construction work, accident case studies, etc. as part of practical training for each year level and position from young to mid-level employees in the construction divisions. Employees who have worked at the Company for a certain number of years and who are in certain positions must participate in this training.

We also implement safety and health education for cooperating companies engaged in construction work together with us. Specifically, in addition to training for foreman-level workers and those responsible for safety and health at cooperating companies, we also hold on-site training concerning the handling of equipment and machinery used in construction work and how to use equipment to prevent accidents. A total of 972 employees participated in these training sessions in fiscal 2024.

In addition, we also have implemented safety and health education for cooperating companies engaged in construction work as partners. Specifically, we have provided training targeted at foreman and personnel responsible for safety and health in these companies.

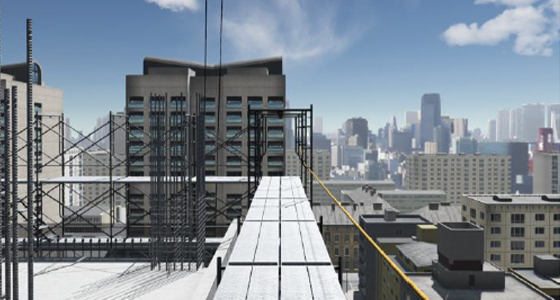

“Experiential safety VR training” using virtual reality (VR) devices was introduced as one of hands-on trainings for cooperating companies in December 2021. By allowing participants to simulate the experience of occupational accidents through realistic VR scenes, we aim to raise their safety awareness.

(experience of falling from temporary scaffolding)

Ensuring safety on construction sites

Before beginning work on new construction projects, Haseko Corporation holds meetings of the Construction Plan Examination Committee aimed at ensuring appropriate and smooth construction. In addition to the Construction Dept. and site foreman responsible for managing the construction site, the Safety Management Dept., the Technical Support Dept., and the Environmental Systems Dept. also participate in committee meetings. They examine the various risks associated with each project and provide guidance and advice to the Construction Dept. and site foreman. Likewise, in terms of safety management, we evaluate risk based on the unique circumstances of each project and implement suitable countermeasures to ensure safe construction work.

After construction work commences, we implement “worksite safety and health patrols,” where employees in the Safety Management Dept. visit all construction sites. Employees carrying out these patrols inspect the status of each site’s safety and health management, the completeness of relevant documentation, etc. based on a checklist, and provide necessary guidance on improvements. The results of these inspections are shared with the Construction Dept. responsposteible for managing the construction site and the officer in charge of the construction divisions. The Internal Auditing Department also audits each form of management implemented by the Safety Management Dept. through its internal audits.

The scope of audits by the Internal Auditing Dept. is not limited to construction sites and includes the status of management related to industrial safety and health, such as audits of the status of working hours management across all divisions, including Group companies.

34 construction sites certified under JFCC’s “JFCC Standards for a Comfortable Workplace”

Haseko Corporation has obtained certification under the JFCC Standards for a Comfortable Workplace with respect to construction sites that have in place proactive initiatives to improve the work environment to retain and develop next-generation workers. In fiscal 2024, 18 sites received “Platinum” certification and 16 sites received “Comfort” certification.

These certifications were a result of the Workstyle Reform Subcommittee’s promotion of value enhancement activities as well as the combined efforts of each construction site, including those of cooperating companies, to improve the work environment.

We will work to increase the number of certified “Comfortable” construction sites through continued initiatives and further improvements.

Status of occupational accidents and initiatives aimed at preventing recurrence

In fiscal 2024, there were 14 occupational accidents resulting in one or more days of lost work time. The main causes were getting caught in equipment (five), cuts and abrasions (two), falls (two), contact with high-temperature or low-temperature items (two), collisions (two), and contact with hazardous substances (one). The accidents resulted from factors such as heatstroke from working in scorching heat, workers’ unsafe actions or lack of hazard awareness, and deviation from work procedures.

When an occupational accident occurs, the Construction Department and the Safety Management Department in the Construction divisions lead an effort to promptly share information, investigate the cause, and propose recurrence prevention measures. We strive to prevent recurrence by disseminating this information horizontally to all construction sites and group companies, as well as to our cooperating companies through cooperating company organizations such as the Safety Cooperation Association and the Ken-ei-kai. As an example of recurrence prevention measures, since accidents caused by heavy machinery and slinging operations often become more severe, we have strengthened education for heavy machinery operators and slinging operators.

In fiscal 2025, we will continue working to achieve our goal of zero accidents and disasters throughout the entire construction period, with a focus on prevention of falls, prevention of accidents from flying or falling objects, prevention of accidents from unsafe behavior, and employee and worker education.

There was also one fatal accident in fiscal 2024. The accident was caused by heatstroke and resulted in the death of a cooperating company’s employee.

We took this accident seriously and revised the existing “Heatstroke Prevention Rules” to comply with legal and regulatory amendments. In addition to strictly reinforcing the management of work hours and rest frequency based on the WBGT (heat index), we further enhanced heatstroke prevention measures, by creating a checklist as a means to increase the frequency of health checks, etc., in order to particularly ensure that changes in workers’ health conditions can be detected at an early stage. Furthermore, we will work with cooperating companies to assess the risk of severe illness in individuals with pre-existing conditions, the elderly, and others at risk of sudden deterioration in health due to heat exposure, and provide them with individualized support. In addition, we increased the use of the heatstroke prevention watches (made by Smartfit and Kurabo) introduced in fiscal 2023, installed sunshade equipment on the uppermost part of building frames, and began a “ drink 1.5 liters of water a day” campaign through the construction divisions to instill the importance of proper hydration. Through these initiatives, we will strive to prevent similar accidents from occurring again.

Analysis and response in the event of an accident

・Information sharing and investigation of the cause led by the Construction Department and the Safety Management Department in the Construction divisions

・Research and analysis at Recurrence Prevention Measures Meetings

・Proposal of recurrence prevention measures

・Horizontal deployment within and outside the company as needed

・Accumulation as accident data and incorporation into safety and health policies and measures

Safety performance

This table can be scrolled

| (Fiscal year) | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|

| Frequency rate | Four work-days lost or more | 0.52 | 0.22 | 0.28 | 0.14 | 0.28 |

| One work-day lost or more | 0.72 | 0.45 | 0.53 | 0.34 | 0.52 | |

| Severity rate | 0.01 | 0.00 | 0.00 | 0.51 | 0.26 | |

Frequency rate: This is the total number of deaths and injuries due to industrial accidents per million cumulative actual hours worked, representing the frequency at which accidents occur

Severity rate: This is the total number of work-days lost per thousand cumulative actual hours worked, representing the degree of seriousness of accidents

*The figures are the results of Haseko Corporation’s construction sites on a non-consolidated basis (calculated including the employees of business partners).

*Average results for all industries and the general construction industry

for the frequency rate and severity rate are shown below.

(Fiscal year)

2020 2021 2022 2023 2024

・Frequency rate (One workday lost or more) Average for all industries1.95 2.09 2.06 2.14 2.10

Average for the general construction industry1.30 1.39 1.47 1.69 1.91

・Severity rate Average for all industries0.09 0.09 0.09 0.09 0.09

Average for the general construction industry0.24 0.41 0.22 0.29 0.57

Number of industrial accidents (number of disasters involving deaths)

This table can be scrolled

| (Fiscal year) | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Haseko Corporation employees (no. of incidents) | 0 | 0 | 0 | 0 | 0 |

| Haseko Group employees (no. of incidents) | 0 | 0 | 0 | 0 | 0 |

| Employees of business partners(no. of incidents) | 0 | 0 | 0 | 3 | 1 |

Promoting health

Basic approach to employees’ health

Since 2008, the Haseko Group has been providing support to its officers and employees for better physical and mental health by promoting "Healthy HASEKO Full-of-life Plan" under the slogan "No success without healthy officers and employees."

To describe its passion for and approach to health at the Group level, we released "Haseko Group’s Declaration of Health" in September 2017 and thereby presented our corporate policy for health to people inside and outside the Group.

Haseko Group’s Declaration of Health

We, at the Haseko Group, hereby make our declaration of health to pursue a group in which all employees—our most important business

resource—can maintain their health, both physically and mentally, and each and every one of them can work more vigorously, in order to fulfill our corporate philosophy "To contribute to society by creating an optimal environment for cities and people."

- Support for health

The Company will proactively work on maintaining and improving its employees’ health and provide support to them for better health. - Responsibility for health

Employees shall take responsibility for their own health and take action and make efforts accordingly on an ongoing basis. - For a healthy future

Our future must be unlocked by no one but ourselves. In order to open the way to Haseko Group’s future, let’s work together and make efforts as a team by giving top priority to our health.

Date of Establishment September 15, 2017

Haseko Corporation

President and Representative Director Satoshi Kumano

Organizational framework for promoting health management

In accordance with Haseko Group’s Declaration of Health, we established the Haseko Group Health Management Promotion Committee in fiscal 2018. The Committee is chaired by the President of Haseko Corporation, its members are the respective officers in charge of departments of Haseko Corporation, the respective presidents of Group companies, industrial doctors, labor unions, and its secretariat consists of the Personnel Dept., the Safety Management Dept., the Welfare Dept. of Haseko Well Center, and the health insurance society. The Committee makes decisions on company-wide policies, targets, plans and progress related to the maintenance and promotion of employees’ health and shares related information.

Health Management Strategy

Under the Haseko Group’s Declaration of Health, with the aim of becoming a Group where all employees can stay healthy both mentally and physically and where each and every one can work with more vitality, we formulated the Haseko Group Health Management Strategy Map visualizing the relationship between the management issues to be solved and the investments in health (health promotion measures) required.

Haseko Group Health Management Strategy Map (Japanese only) [PDF:541KB]

Employees’ health status (metrics) (Japanese only) [PDF:642KB]

Maintaining and enhancing health

Physical health

HASEKO CLINIC," an in-house medical office that serves as the health management and disease prevention center for Group employees, plays a pivotal role in our efforts for the early detection of diseases through medical checkups and outpatient treatment. The CLINIC has precision equipment comparable with hospitals and is capable of performing accurate and speedy tests.

The CLINIC not only conducts periodic medical checkups on all employees but also holds health seminars (e.g., improvement of diabetes, smoking cessation) andgives advice for the prevention of lifestyle-related diseases, in an e ort to enhance their health. Under the scheme for raising employees’ awareness of good health, certain employees are offered PET-CT scanning, while female employees are entitled to comprehensive women-only medical examinations.

Mental health

We have a structure in place to provide care to employees to maintain their mental health ranging from counseling to reinstatement assistance, including stress checks, as well as a structure to give support to employees in the event of the onset of mental illness.

Specific services available are: "self-care," which involves counselling and telephone consultation by a professional body outside the Group; "line care," which is a periodic training session held for managers to educate them and raise their awareness for the prevention of mental illnesses among their subordinates; and "reinstatement assistance program," in which a support team including an industrial doctor and the personnel division provides employees with full support at the Company level to return to work.

Refreshing

The Haseko Group believes that it is important for employees to have opportunities to expand their horizons in terms of hobbies and mates

and opportunities to refresh themselves, in order to maintain their physical and mental health. For this reason, we not only directly operate a recuperation facility but also introduce recuperation facilities and resort condominiums to employees and encourage employees to utilize them.

Furthermore, "Haseko Club" and "Everyone's Event," which are open to employees of the Haseko Group, provide the employees with opportunities to refresh themselves through physical exercise and cultural activities.

2025 Certified Health & Productivity Management Outstanding Organizations Recognition Program (White 500)

Haseko Corporation and its affiliates were recognized under the “2025 Certified Health & Productivity Management *Outstanding Organizations Recognition Program” in the large enterprise category hosted by the Ministry of Economy, Trade and Industry (METI) and Nippon Kenko Kaigi as one of the “organizations engaging in strategic health and productivity management program efforts for maintaining their employees’ health from a management perspective.”

*The term “health and productivity management” is a registered trademark of the Workshop for the Management of Health on Company and Employee.

- Related information

Initiatives on labor issues

Support of living wage

Haseko Corporation conducts labor management in compliance with labor laws and regulations in each country and region. As for wages, we comply with minimum wage standards stipulated in each country and region, and pay higher wages than the standards as our basic policy. The average annual salary of the Corporation was 10.58million yen in fiscal 2024.

Labor-management relationship

The Haseko Group has nurtured labor-management relations built on mutual trust between the Group companies and the Haseko Group labor union, and believes that as a company, it is a fundamental necessity to respect the right of freedom of association, the right to organize, the right to collective bargaining, and the right to collective action, all of which are enshrined in its collective agreement. Aiming to realize a work-life balance for every union member and the development of the Group, the labor union collects voices from union members through questionnaires on their living and working conditions as well as meetings at worksites. Based on these voices, discussions and suggestions are made on equal footing through regular meetings between the employer and employees about developing a reassuring labor environment and measures for improving productivity. Each company takes these matters seriously to consider and implement various measures for the further development of the Group.

Risk assessment concerning labor issues

Each company in the Haseko Group monitors working hours as part of their employee work safety risk assessment, and reports the results to the Management Council on a monthly basis.

Based on the results of the monitoring, we take the following measures to ensure employee health and prevent overwork.

• We have formed “MOSt (Move on Step) Committees” composed of labor and management personnel at each division of Haseko Corporation and within each Group company, to examine measures to reform operations, enhance productivity, and shorten working hours.

• We have established “Group-wide leave work early day” (twice per year) and “division early finishing and going home early day” (more than once a month) as common measures across the whole Group.

• We apply overwork interview rules that are stricter than the statutory criteria.

We also monitor the status of employee health and promote initiatives to maintain and improve the health of our personnel through the “Haseko Group Health Management Promotion Committee.”

In addition, when considering M&A, HASEKO Corporation assesses work safety risks as part of due diligence after confirming the target company's status of accidents and disasters, status of long-term absentees, and status of labor issues as the decision-making factors for such M&A.

- Sustainability TOP

- Message from the Management

- Message from the Officer in Charge of Sustainability Promotion

- Haseko Group's Sustainability Management

- Climate Change Response

- The Digital Transformation Strategy of the Haseko Group

- D&I at the Haseko Group

- Creating attractive living spaces

- Building a company worth working at

- Protecting the precious environment

- Nurturing a culture of trust

- ESG Data and Disclosures

- External Evaluations and Awards

- Integrated Report

- Philosophy and Policies

- Special feature archives